Update – april 2021

Dear Sercom relation,

After a long and difficult period of uncertainty within the horticultural sector, in which many of our relations have had to fight for the survival of the company, I now slowly dare to look ahead with some hope and positivity. From my office in Lisse I see the first bulb fields blooming. I like to see that as a metaphor for the recovery and growth of our sector.

The past year has also been very special for Sercom. We have done everything we could to make things run as smoothly as possible. We have even succeeded in developing new products and entering new markets. Below I would like to give you a brief overview of some important or interesting news facts within our company.

First big order for China finally delivered!

At the end of 2019, just before the outbreak of the current Covid-19 crisis, we sold our first major project in China. This is a completely new project in Chengdu, where mini roses are grown in pots. Unfortunately, it was not possible to deliver and install this order in the past year. But earlier this month, exports to China were finally released and the materials are on their way!

It concerns an extensive process computer; the SC800. The computer will be used to control both the climate and the irrigation in the new greenhouse. Two dosing systems for mixing water with fertiliser are also controlled. We also hope to have taken the first step towards further developing our capabilities in China. With our new local partner NCU Group Ltd. we are very confident about that.

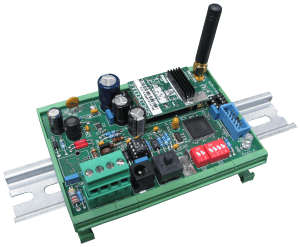

New PCB for wireless connection between process computer and control PC

After the introduction of the Wireless Xtender, with which a wireless connection can be made between the climate computer and individual field stations, we continued this development with the introduction of a PCB that enables a wireless connection between the process computer and the control PC.

This print can easily be connected to the operating PC or laptop in the office. The same print can be placed in the process computer on location. After this, a connection is automatically established between the two locations. Then it’s possible to monitor and operate the climate computer within a distance of 5 kilometers.

This technology, which is based on radio waves, just like the Wireless Xtender, is not limited to a connection between the process computer and the operating PC, but can be applied to any system or device that works with an RS-485 cable connection as standard.

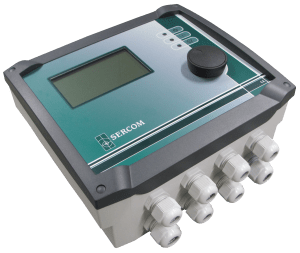

Expansion of the SC400 range

After the introduction of the SC400, the process computer that focuses on one greenhouse section or only irrigation, we have further developed this system into several models that are tailored to the individual requirements within the greenhouse or watering.

We started with one version for climate management and one for fertiliser dosing. Meanwhile, four models have now been developed for each of these functions. This makes it easier to choose the SC400 system that best suits the situation and wishes of the grower.

For the climate versions, a distinction is made between the control of various aeration systems and screens, heating and the management or otherwise of functions such as lighting, CO2 and misting. For the irrigation version you can choose between controlling EC and/or pH and managing the pumps and taps without further additives, such as occurs in tree nurseries or cultivation in open fields. The new versions also remain very competitively priced.

New SC400 mini weather station

For the SC400 we have developed a special weather station. Which is supplied as a fixed part with the climate versions and can optionally also be included with the irrigation models. Externally the weather station is similar to the SC600 and SC800 weather station.

The weather station is supplied as a set without mast, including a handy connection bracket set for mounting the sensors on the mast. Internally, the weather station print has been cleverly adapted so that it only communicates with the SC400 with a four-core shielded cable. Click on the image to enlarge it.

Various projects for storage cells

In addition to our growing activities within greenhouse horticulture, Sercom is an important supplier of process computers for storage cells. Here, in The Netherlands for example, we are the market leader in controlling storage cells for flower bulbs. In Scandinavia, Germany and Russia, we have an ever-increasing market share in storage cells for potatoes/onions.

Recently, commitments have been made to a number of large flower bulb companies to expand their existing Sercom system with hardware and software. Among those, the firm Triflor in Oude Niedorp, a very important and leading supplier of tulips, has continued to modernise their three Sercom computers. The oldest computer was already delivered in 1992. Thanks to the upgrade, it is not inferior to the most recent computer installed just a few years ago.

With the help of the modern ARM processor board, the process computer (not to be confused with the PC for operation) is now connected to the internet and additional software can easily be added or adjusted. If desired, we can also view the process computer from Sercom and make real-time adjustments.

In addition, they now have access to the software application SercoView on the PC, with which one can create a graphical representation of the company and see at a glance what and how the various functionalities operate. Of course you can zoom in on a department or cell or on individual equipment to be able to operate it.

General increases in delivery times and prices

In recent months, shortages of various raw materials have arisen worldwide because manufacturers have produced less than normal for a period of time. This includes plastic, paper and metal.

Recently, the demand for production and products has increased again. The result of the increased need and increasing demand is the extension of delivery times and the rise in prices. It is not known when the market will normalise. A number of suppliers of injection moulding materials indicate that they expect to experience difficulties until at least Q3.

Unfortunately, we cannot predict which materials we use will be affected as we make purchases per order. We ask you to try to take longer delivery times and possibly higher prices into account. The new price lists for 2021 will be sent in April. We have not yet had to increase the prices except for the normal annual indexation. We hope, of course, that this will remain the case.

Finally

I hope that this spring has started a further recovery for all our relations within the horticultural sector and that we will soon be given the opportunity to speak to each other in person again during a trade fair, meeting or visit to your company.

Kind regards,

Jan-Willem Lut